Vise Series

COMPACT GRIP

Compact, Rigid & Accurate!

Not only for 5th axis machine

5 years warranty

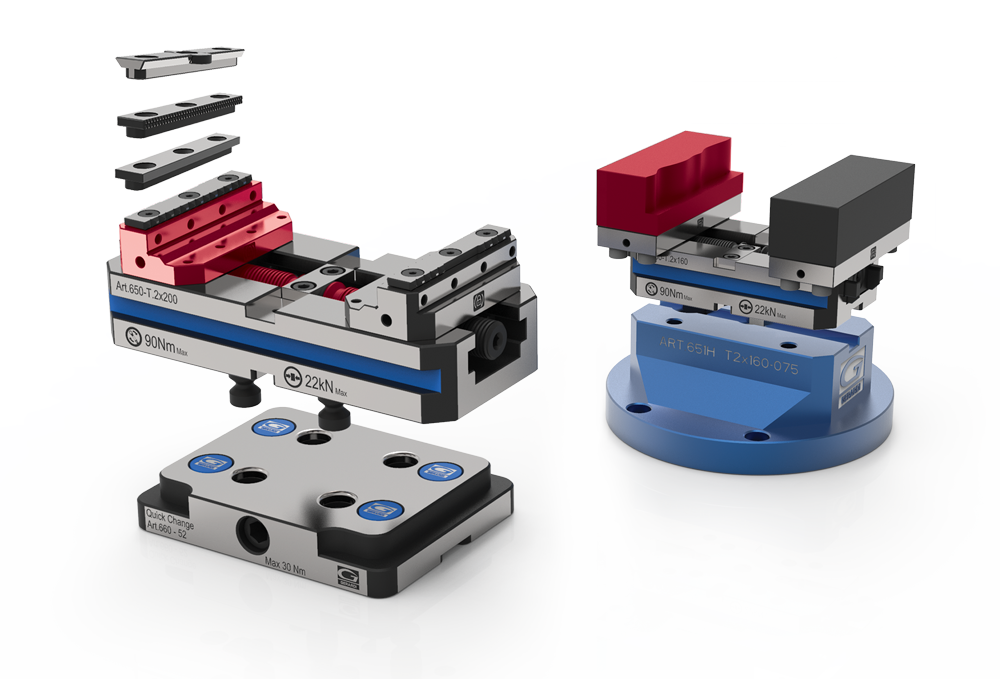

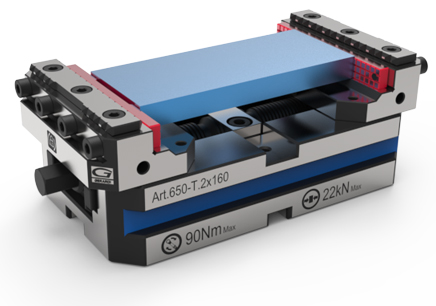

Designed for 5 axis machines, this series of vises allow machining operations on the 5 workpieces sides with perfect alignment in a space saving design, extremenly high wear resistence, with reduced deflection. Max compatibility with the most popular pallet change systems.

Their name indentifies the main vise features which are the extreme compactness and easiest handling and the system

of inserts which it adopts, so called “GRIP”.

This system includes a range of jaw inserts assembled on the top of the main jaw with the function of clamping the workpiece through sharp or duly shaped teeth according to the material type and hardness to clamp.

the most

compact

vise series

Watch the presentation video of the Gerardi CompactGrip vise series

Vises for advanced applications on 5th axis machining centres

features

ACCURACY ±0,005mm

HARDENED 58±2

highest clamping power

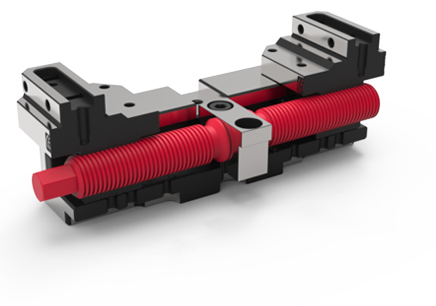

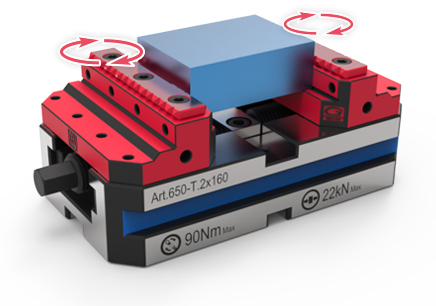

Much higher clamping power than the existing vises, but also compared to our Art.640 and with a more compact and lighter design. This is because of the clamping screw design, its position much closer to the workpiece, and the integral design of slides and jaws.

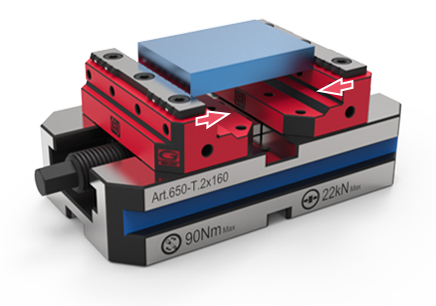

SELF-CENTERING ADJUSTABLE

Easy self-centering adjustment from the top by key-nuts supplied as standard equipment.

Versatility !

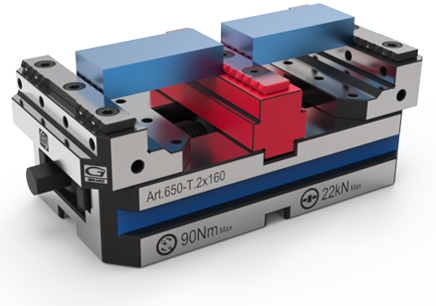

wide range of jaw inserts

Inserts to be used on both sides Another advantage will be the greatest versatility thanks to easiest and quickest GRIP top jaw inserts exchange with different types of teeth design to be used according the material to be clamped

frontal JAW inserts

SOLID GUIDED

REVERSIBLE JAWS

Versatility also thanks to the SOLID GUIDED reversible jaws and to

the 4 base positions option (90°) and to the front through holes.

from single to double

Transform you vise from single to double using the Intermediate Jaw.

ZERO POINT READY

Save up 95% set up time by using Zero-point. Set-up for the quick and safe positioning of the vise on Zero Point system. The easiest and most effective way to decrease set up time and increase profits.

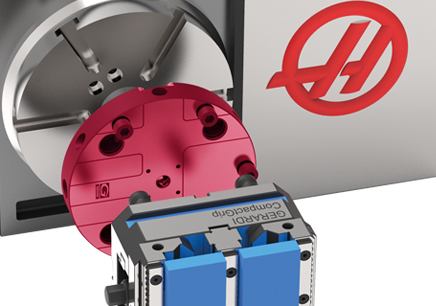

Compatibility with 4th axis

The new Quick Change Sub Plate Art.660 (available also as round Art.661) allows the quick of vises or fixtures replacing on the most famous rotary table. The machineable version can be tailor made by the customer himself according to his machine table.

PRODUCT NOT AVAILABLE FOR GERMAN & AUSTRIAN MARKET

customized solUtions

Find out some customized solutions for all your clamping problems