cnc lathes & vdi turrets

DRIVEN TOOLS

More than 1000 types available

2 years warranty

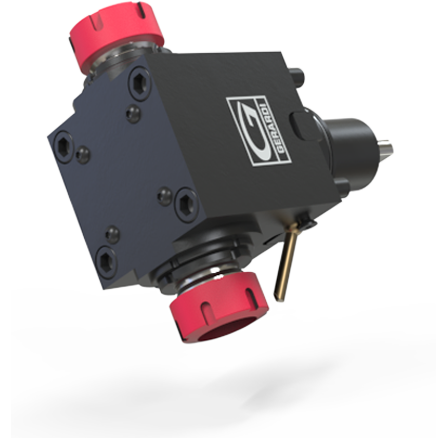

Driven tools for CNC turning centres allows milling, drilling and tapping operations on the lathes without additional parts handling. Also in this case Gerardi can suplly a wide range of types in order to equip the CNC lathes and turrets of the most popular builders on the market with an unbeatable price/quality ratio.

vdi

bmt

VDI ToolHolders consist of a serrated shaft that is inserted into an opening on the face of the turret. The toolholder is locked in place by a mating part with teeth located inside the turret… when an Allen wrench is used to tighten the locking screw, situated on the turret face, the mechanism activates and holds the toolholder firmly in position. The rotation of the toolholder is prevented by a pin located on the mounting surface of the turret. Unlike BMT toolholders, VDI toolholders can be mounted either on the outer circumference of the turret or on its face, depending on the turret configuration of the machine in use.

The BMT, or “Base Mounted Turret”, is a popular choice when seeking a more rigid configuration. The BMT holder is securely fastened to the face of the turret with 4 socket head cap screws, and is positioned and further secured with locating keys present on the turret face. Thanks to these keys, it is not necessary to indicate the toolholder to straighten it, which is often required with VDI toolholders. Additionally, the simple design of the BMT holder’s mounting configuration makes it an excellent choice for creating custom holders for special circumstances – something that would be very difficult with VDI toolholders.

features

HIGH SPEED 24.000 Rpm

INT. COOLANT UP TO 100BAR

Main body Treated

Specially treated corrosion resistant steel body

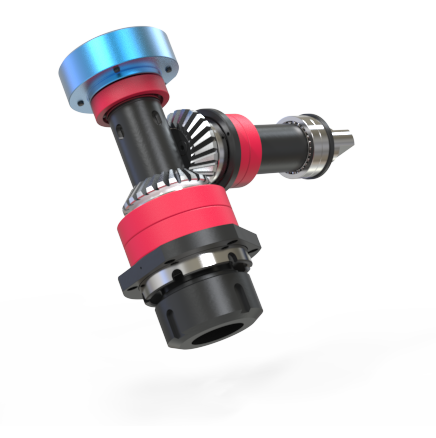

Ball Bearings

Preloaded angular contact ball bearings precision and long life lubrication.

Gleason Spiral bevel gears

Gleason spiral bevel gears with completely ground involute form

Tapping

For tapping operations all driven tools can be equipped with axially compensated collets ET-1 interchangeble with the standard ER collets according the international standard DIN 6499. They allow the tap an axial compensation from 7 to 13 mm according to their size in order to compensate any feed error and the inversion of the rotation of direction.

multiple outputs

All the driven tools, with the exception of those with adjustable angle, can be supplied with double or multiple output even of the same dimension. Multiple outputs can be opposite or with the same direction.

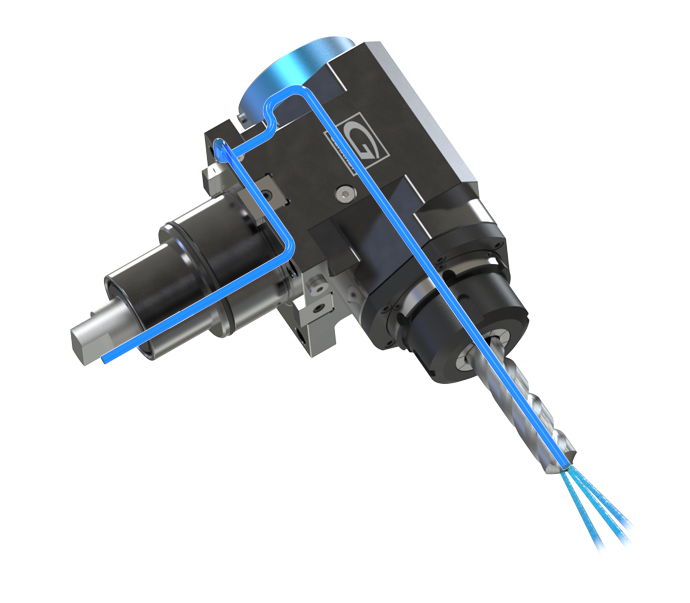

coolant

external

» Machine Spindle »

Coolant Pipe

internal

» Machine Spindle »

Rotating Distributor » Tool

re-cool NUT

» Machine Spindle »

Re-Cool Nut » Tool

customized solUtions

Find out some customized solutions for all your machining