Automatic Vise Series

STANDARD MATIC

The perfect mix!

Price, Quality, Versatility

5 years warranty

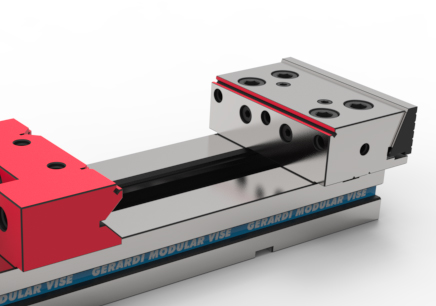

All GERARDI vises and accessories are modular and components of all our vises will interchange with perfect alignment.

The vises can be matched side to side with the highest precision and minimum of set up times thanks to many fixed reference points.

All this is possible thanks to the high precision of the vise particularly as regards: the base high, the alignment with longitudinal key-nuts with respect to the fixed jaw, the perpendicularity of the fixed jaw with respect to the vise base and the parallelism of the base top and bottom surfaces.

Those features allows us to solve the most varied and complicated problems of clamping in a few seconds with the use of more vises.

precision steel

modular vises presentation

Watch the presentation video of the Gerardi precision steel modular vises.

The most popular and copied vise in the world!

features

ACCURACY ±0,005mm

HARDENED 58±2

Solid guided jaw

Both jaws bodies are built in one solid piece (no slides or key-nuts): in order to guarantee higher rigidity & no bendings. Both jaw plates are manufactured with a pull down angle. This ensures, during the clamping operation, a downward run of the workpiece against the vise base (by dragging) and thus a precise and safety clamping.

Prismatic jaw

The prismatic jaw Art.217 allows the clamping and machining of vertical and horizontal round workpieces or to clamp rised workpieces for drilled through on the step

Threaded holes for stack type jaw

4 extra tapped holes over the jaws for special Gerardi stack type jaw application

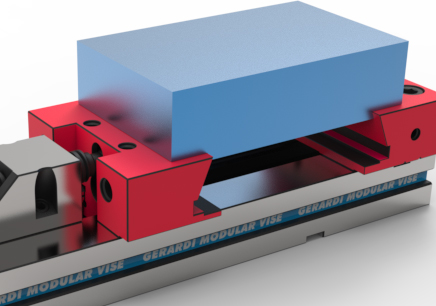

Versatility

Fixed jaw with 5x5mm step matchable to the prismatic movable jaw (Art.217 to be ordered separately) which allows to clamp plates without parallels and round workpieces vertical & horizontal way. Vertical, sideway and gang operation are possible with the appropriate components (column, narrow width jaws, etc.) Unlimited calmping range.

Highest Accuracy

Solid vise base. Every sliding and coupling surface is ground. Centesimal tollerances are guaranteed by checking cycles with CNC measuring machine. The perfect alignment with the machine axis is given by longitudinal and cross keyways (16H7) or positioning holes (Ø16 mm F7), upon specific request, on the vise base. Of course this allows minimum of set up times and gang operations.

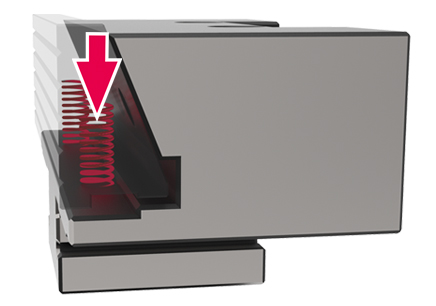

Dove tail system

By taking off the jaw plates, it is possible to exploit the body inclination of 15° to clamp the workpiece and premachine the lower surface thus obtaining an irreversible dovetail system.

customized solUtions

Find out some customized solutions for all your clamping problems