Vise Series

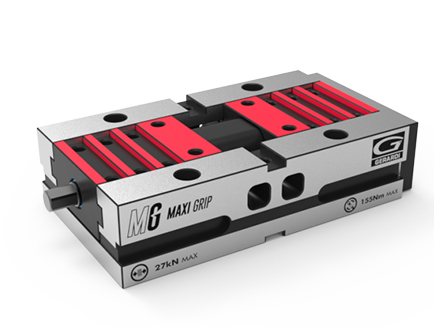

MAXIGRIP

Single, Double &

Self-Centering Clamping

5 years warranty

Maxigrip vises represent the ideal combination between Compact Grip and FMS vises as they ensure safe clamping and high versatility. These vises can in fact easily switch from single to double simultaneous clamping, also of workpieces of different sizes, thanks to the floating system of the yoke and the screw. As easy as this, it is possible to switch to self-centering clamping mode.

This versatility, combined with the reduced overall dimensions, makes MaxiGrip vises suitable for any type of machine, from 3 to 5 axes.

Base body, slides and screws are made of hardened and ground steel in order to maximize their life and ensure performance stability over the time. These performances are further enhanced by the use of bearings, that improve the sliding of the elements, and by a seal, which grants the correct lubrication of the mechanisms.

To provide a solution that is perfectly integrated with customer’s final production, MaxiGrip vises are compatible with Gerardi Zero Point system as well as pallet change systems available on the market.

These vises can also be equipped with interchangeable Grip inserts, available with different types of teeth for the most proper clamping of various materials in order to grant stable machining even when the workpiece is grabbed by a few millimetres only.

the most

compact

vise series

Watch the presentation video of the New Gerardi MaxiGrip vise series

Vises for advanced applications not only for 5 Axis CNC

features

ACCURACY ±0,005mm

HARDENED 58±2

bearing and seals

Internal bearings and seals are conceived to improve sliding and to keep a correct lubrication of the cinematic movements.

slides

The vise base, slides and screws are made of hardened and grounded steel. The Slides allow many jaws positioning

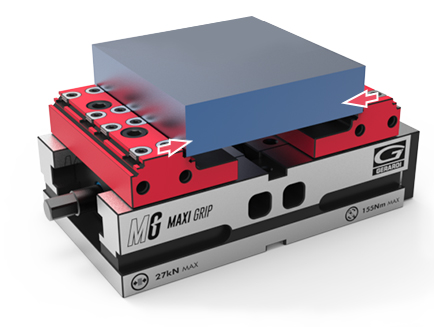

SELF-CENTERING CLAMPING

During the self-centering clamping, the workpiece will be clamped by the vise and automatically centered. The setting system to make it possible, is easy and intuitive: an hex wrench allows to loosen the yolk screws through the jaws holes, thus allowing the tilting of the screw wagon so that the movable jaws reach the mechanical stop against the fixed jaws and ensure a correct alignment.

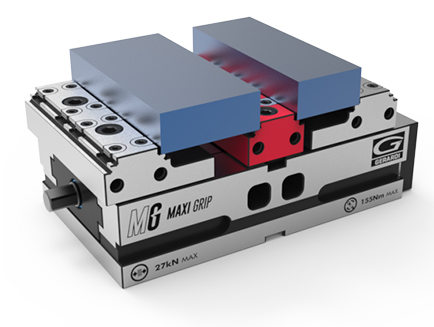

DOUBLE CLAMPING

& JAWS ROTATION

For double clamping, remove the screws that press the yolk and install the fixed jaw so that the vises can simultaneously clamp two raw pieces thanks to the grip inserts. After the first machining stage, the workpieces can be turned and clamped on the smooth step for the last stage of machining. The jaws can rotate of 180°allowing to clamp very small workpieces too.

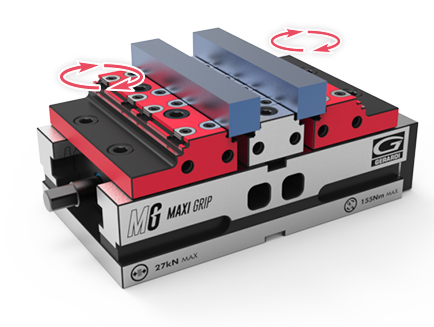

SINGLE CLAMPING

It is possible to change the clamping system from self-centering to single clamping. To do this, block the slide with a containment plate using the movable jaw as a fixed jaw with the possibility to end the machining in two stages.

TOP JAW INSERTS

The Jaws are equipped by interchangeable grip inserts with several teeth types, suitable for the clamping of different materials.

ZERO POINT READY

The MaxiGrip vise is 100% compatible with the Zero Point dipositioning and anchoring system and Quick Change Plates.

Using the Zero Point System is the easiest and most effective way to reduce set-up time, saving up to 95% of time and increasing profits.

customized solUtions

Find out some customized solutions for all your clamping problems