Vises & Vise Towers

XL SERIES

to clamp workpieces

of unusual dimension!

5 years warranty

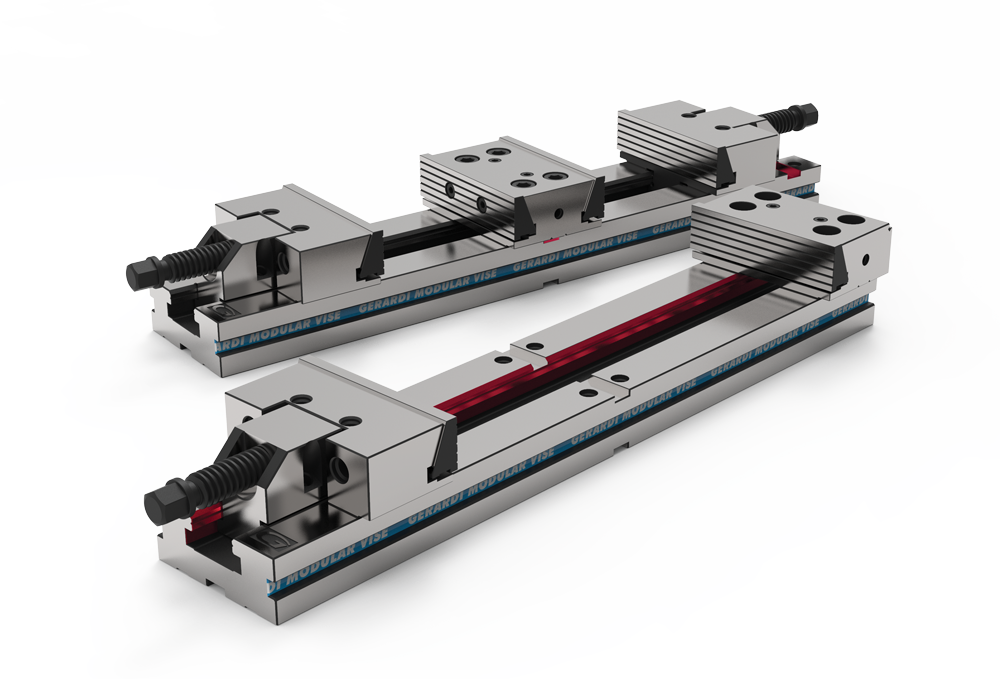

As the Standard vises but with a loooonger base !!

Space on the machine table is sometimes limited: XL vises enable to have 2 vises in 1 because they can quickly change from double vise to single vise with very large opening.

Double XL vise allows to machine more workpieces using the total length of the machine tool, this means to increase productivity of the workcicle and of the machine.

Single XL vise allows to clamp pieces of unusual dimensions and plates (with the right jaws).

The very wide range of widths and lenghts of bases guarantees the satisfaction of the widest variety of works and a big rigidity of the fixture too. In conclusion all this allows to reduce to a minimum dead times/interruptions and consequently faster payback period of machines and fixtures.

On request all vises can be supplied with key-nuts of different sizes or with ground holes.

precision steel

modular vises

presentation

Watch the presentation video of the Gerardi precision steel modular vises.

XL series, as the Standard vises but with a loooonger base !!!

features

ACCURACY ±0,005mm

HARDENED 58±2

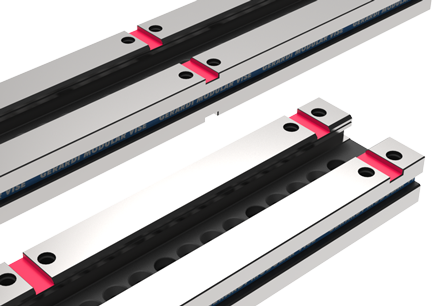

Double fixed jaws

Double fixed jaw position both in the center of the vise base (for double clamping) and at the end (for single big workpieces Clamping). Double XL vise allows to machine more workpieces using the total length of the machine tool, this means to increase productivity of the workcicle and of the machine

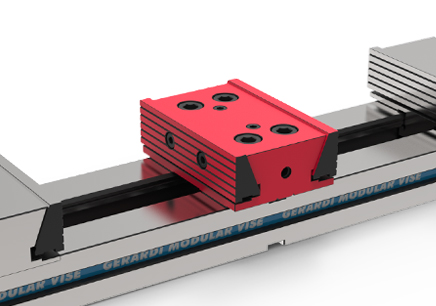

Independent clamping

Two independent clamping devices

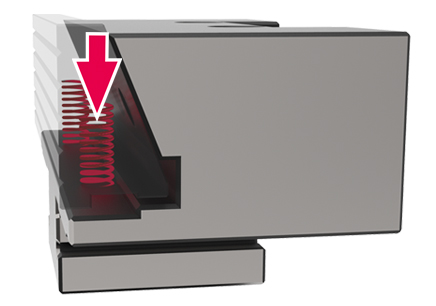

Solid guided jaw

Both jaws bodies are built in one solid piece (no slides or key-nuts): in order to guarantee higher rigidity & no bendings. Both jaw plates are manufactured with a pull down angle. This ensures, during the clamping operation, a downward run of the workpiece against the vise base (by dragging) and thus a precise and safety clamping.

Two keyways on the top side

Two differents keyways for two alternatives positions

of the double fixed jaw

Highest accuracies

Solid vise base. Every sliding and coupling surface is ground. Centesimal tollerances are guaranteed by checking cycles with CNC measuring machine. The perfect alignment with the machine axis is given by longitudinal and cross keyways (16H7) or positioning holes (Ø16 mm F7), upon specific request, on the vise base. Of course this allows minimum of set up times and gang operations.

customized solUtions

Find out some customized solutions for all your clamping problems